FLUX BAKING and RECOVERY SYSTEM

TECHFLOW is one of the pioneers in the design and manufacture of all types of flux supply, flux recovery, flux heating, flux screening, flux baking and flux conditioning. For example, flux recovery technology is designed for productivity, worker safety, regulatory requirements, and delivery. Optimal performance with the lowest feasible operating costs.

What is Flux Baking in Submerged Arc Welding?

The granular flux used for welding is a type of granular insulating material composed of a large number of small particles. In submerged arc welding (SAW), granular flux covers the weld and protects it from sparks and spatter. In SAW, granular flux is often the means to achieve high retention. Flux also helps to produce the common types of high quality welds in this particular weld process.

The flux is fed to the flux baking oven where it is baked and soaked to prepare for Submerged Arc Welding operation.

Discover moreWhy Flux Baking is important?

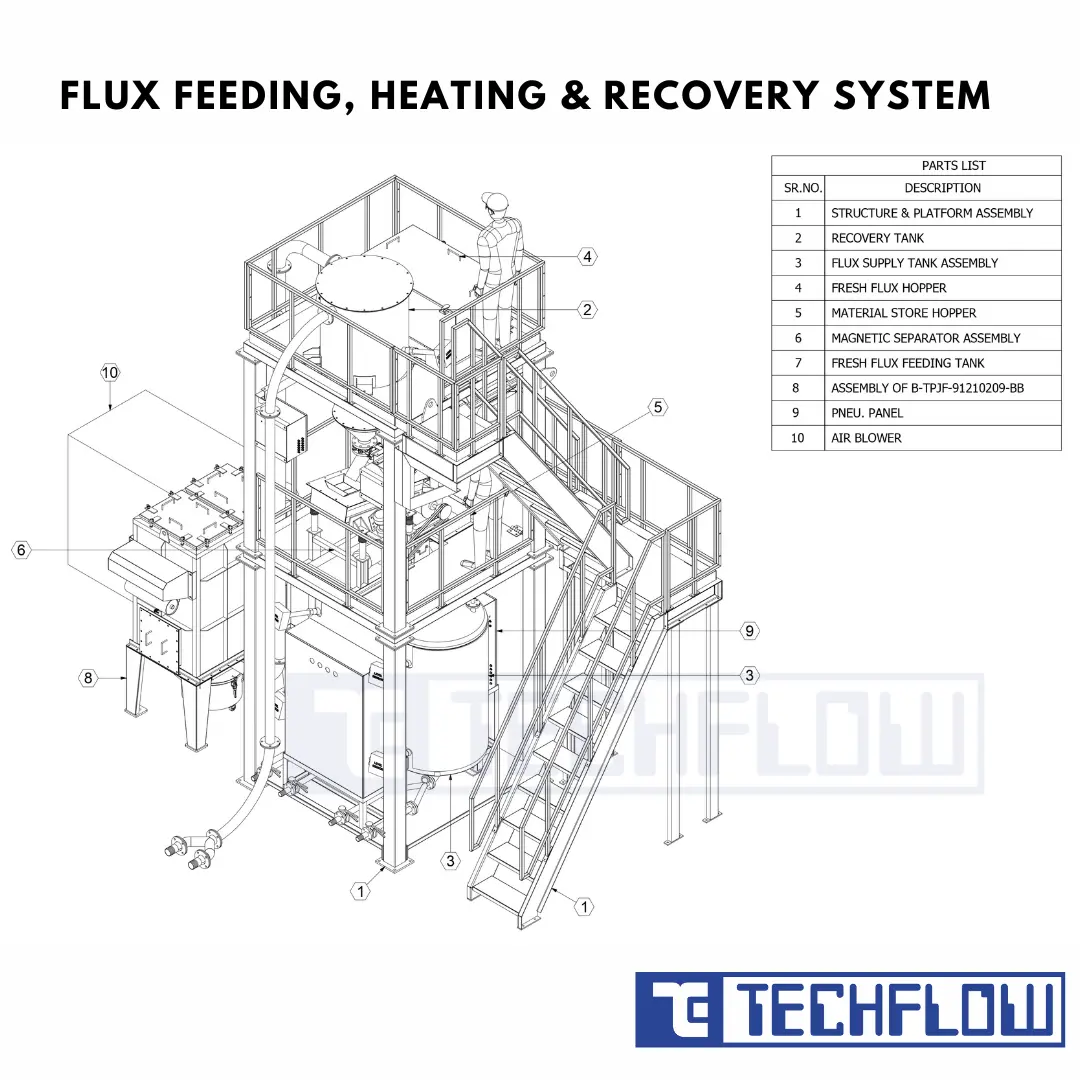

A flux baking and recovery system be categories as below:

Welding Flux Baking & Recovery Unit:

Submerged Arc Welding Flux Baking System:

The submerged Arc Welding Flux Baking System is an important mechanism to compile the Additional flux after welding Operations. It is functioned with a centrifugal blower to construct suction in the hopper. Due to the raised vacuum surplus flux is sucked and collected in the hopper. Because of the forced gravity, welding flux is carried downwards and fills the welding area. These two procedures work parallel so that welding flux baking is automatized. Further flux will be bundled in a hopper in contact interval periods.

The internal heater unit heats up the Welding flux oven. The next temperature modification will be obtainable with the control panel. The magnetic filter stops the metal waste from getting mixed in the welding flux.

You can effortlessly attach our system to your welding automation unit. Powerful suction sucks the flux in a bit of time to the hopper unit. An automated filter cleaning system or manual filter cleaning system enhances the suction execution of the vacuum unit. Some portion of flux is also retained in the collection tank for reusable purposes. Three-phase filters boost the filtration efficiency of the flux baking unit.

Techflow Flux Baking & Recovery System

Techflow Enterprises Pvt Ltd are the most trusted manufacturer of Flux Recovery System from India. We have successfully installed Flux recovery units in well-known SAW plants in India and overseas.